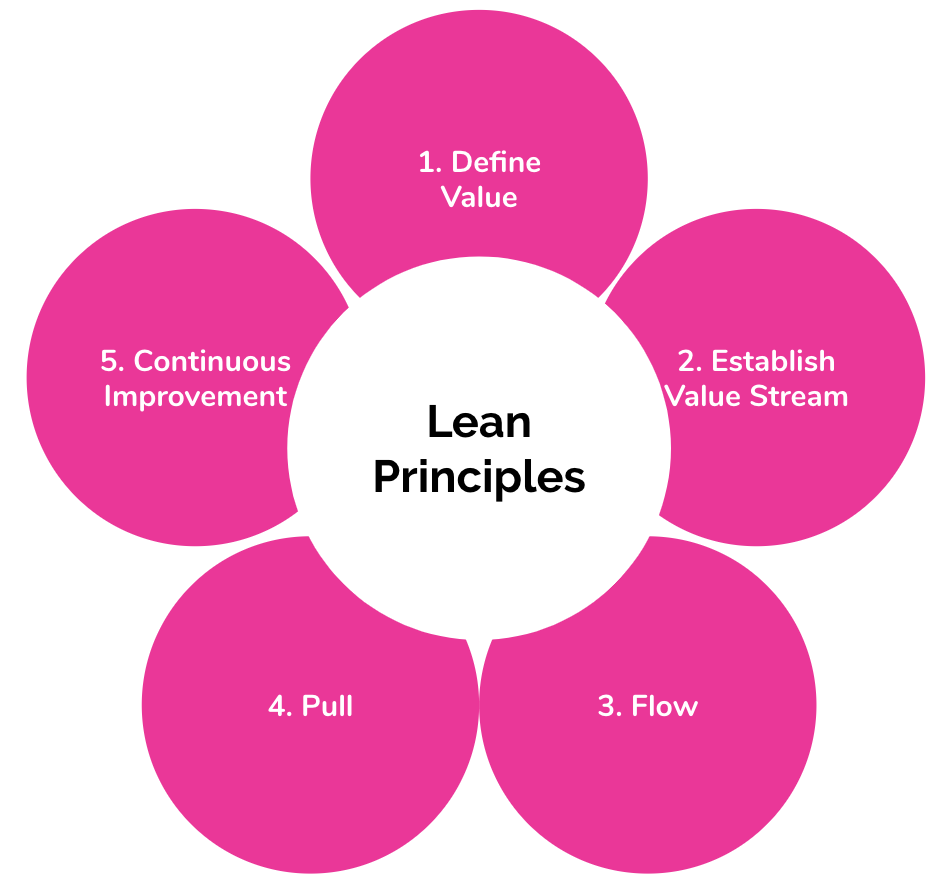

Lean Principles

The 5 Lean Principles:

- Define value from the customer's perspective.

- Identify the Value Stream

- Make Value Flow

- Pull from the Customer Back

- Strive for Perfection

Define value

- “The critical starting point for lean thinking is value”, the authors say.

- The value is set by the customer. In other words, what product and/or service are they willing to pay for. Anything that does not fit into that description, is not value.

- According to the authors: “Lean thinking therefore must start with a conscious attempt to precisely define value in terms of specific products with specific capabilities offered at specific prices through a dialogue with specific customers.”

- The status quo is that manufacturers make what they make without regard what the needs of the customer are. Often customers are not aware of what to ask of the products they are getting.

- Lean Thinking requires companies to discover what customers believe satisfies their needs.

Identify the Value Stream

The value stream is defined as all activities that add up source, make, and deliver a product to customers. With that in mind, we must identify activities that add value and waste (muda). There are two types:

- Type 1 muda: create no value but unavoidable with current technology

- Type 2 muda: create no value and are avoidable

Make Value Flow

After eliminating all possible waste (Type 1 muda) in the value stream, you must make the value-added steps work together continuously (no waiting, stopping, or rework). Several things to consider:

- Set up just-in-time production and deliveries.

- Eliminate specialized departments.

- Focus on the end-product itself and what is required to complete a single product.

- Ignore boundaries between companies, departments, and individual roles with the goal of “removing all impediments to the continuous flow of the specific product.”

- Redesign processes so production of the product can flow continuously.

Pull from the Customer Back

The goal is to deliver only what customers want and when they want it (Pull), rather than pushing products out and guessing that customers might want them.

- For example: “No one upstream should produce a good or service until the customer downstream asks for it.”

- Real-time signals indicate to upstream activities when more is needed.

Strive for Perfection

The improvement of processes never ends: you must always strive to source, make, and deliver a better product while improving efficiency.

- “Form a vision, select the two or three most important steps to get you there, and defer the other steps until later.”

- Don’t settle for just being better than your current competition, because someone will come along and top you.

- Practice transparency across the entire value stream to discover opportunities for improvement.

No comments